Peltier temperature control is becoming more common in viscosity testing, but traditional water baths are still the norm for many companies. Should you switch Peltier-based temperature control for you critical samples?

Read MoreNew Methods of Controlling Sample Temperatures [Water Baths to Peltier Plates]

Posted by Amanda Ranowsky on Jun 24, 2019 8:30:00 AM

Topics: Measure Viscosity, Viscometers, Viscosity, viscometer, rotational viscometer, differences in rotational viscometers

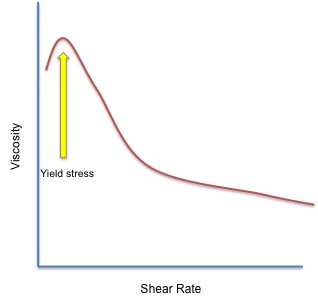

What are Viscosity Flow Curves?

A flow curve – also known as a rheogram – is a graphical representation of how a flowing material (fluid) behaves when it is subjected to increasing or decreasing shear rates. The corresponding shear stress and viscosity are calculated from the instrument’s parameters. You can tell what type of fluid (Newtonian/Non-Newtonian, thixotropic, dilatant, etc.) the sample is by the shape of the flow curve.

Read MoreTopics: Measure Viscosity, Viscometers, Viscosity

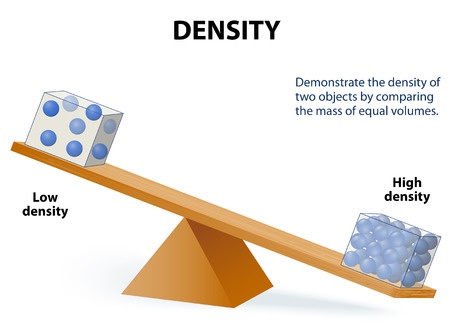

The first recorded application of density measurement was for fraud detection. The density measurement concept then expanded to encompass determination of material composition and assessment of product quality.

Read MoreTopics: density, oscillating u-tube, liquid density, hydrometer

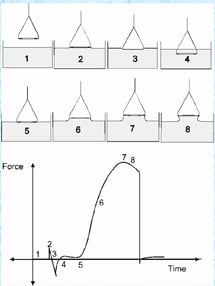

Surface Tension by duNouy Rings or Wilhelmy Plates – Which to Choose?

Posted by Art Gatenby on Jul 16, 2018 5:34:18 PM

When tempted to think I know all there is about surface tension measurement, further information brings me back to earth. I’m conversant with the principal applications: surfactant analysis, plating, detecting contaminants, development of ink and the like. I have assisted customers to set up and calibrate duNouy Ring tensiometers for most applications -- all the while taking for granted that the Ring technique was the method of choice -- with only infrequent questions arising about Wilhelmy Plate tensiometers.

Topics: Wilhelmy Plates, duNouy Rings, Tensiometer, Surface Tension, interfacial surface tension, Liquid Properties, surface tension instruments, surface tension analysis, Digital tensiometer, automatic Tensiometer

Do You Re-Certify? Compare with a Master Stack? Check with Calibration Samples?

What Does Recertification Give?

The ASTM E-11 committee has done a great job of establishing three levels of testing. These levels show the probability of a sieve’s mesh to be within the permissible variations. These variations relate to the size of openings in wire-cloth used for test sieves.

Read MoreTopics: Sieve Shakers, Mid-Point Sieves, ASTM, Particle Size Analysis, Sieve Calibration, Sieve Certification, Sieve Testing, Sieving Process, Quiet sieve shakers, RoTap, sieving, test sieve equipment, sieve mesh

Four Reasons Why Food Manufacturers Should Monitor Moisture

Posted by Amanda Ranowsky on Mar 12, 2018 8:00:00 AM

Topics: Moisture Oven Test, Moisture Analysis, Moisture Testing, CSC Digital Moisture Balance, Loss-On-Drying, Moisture, fast moisture test, moisture balance, moisture content, moisture measurement

Sensational Food Texture - What is It? - How to Analyze it?

Posted by Amanda Ranowsky on Feb 13, 2018 6:30:00 AM

“It doesn’t matter how it looks as long as it tastes good.”

This statement has long been my philosophy when it comes to cooking. The dishes I create usually taste okay – even really yummy, occasionally – but I stink at presentation. Family and friends are usually quite forgiving when it comes to their sensory (sight, touch, smell) experiences with a food. They tend to ignore looks and feel, and focus on taste.

Food buyers aren’t so forgiving. If their sensory experiences don’t meet expectations, that crucial first taste will never happen. Flavor isn’t everything, either. If the food doesn’t feel right, or pleasant, the first bite will also be the last.

Read MoreTopics: Texture Analysis

We’ve all heard of Density since general science class in middle school. "The weight of a 12 ounce Coke." That’s pretty simple.

Read MoreTopics: Liquid Properties, density, oscillating u-tube, liquid density

What are Liquid Properties? Why Should Anyone Care?

Posted by Art Gatenby on Aug 10, 2017 2:59:24 PM

The first question is, "What are Liquid Properties?" Are they some kind of underwater real estate?

Read MoreTopics: Automatic Surface Tension Measurment, Measure Viscosity, Consistency, contact angle, Liquid Properties, density

How Much Do Rotational Viscometers Cost - And Why?

Posted by Amanda Ranowsky on Apr 19, 2017 8:15:00 AM

Looking at the rotational viscometers on the market today, you'd expect to see small price differences between the instruments offered by competing brands. But what if you find one viscometer priced at $2000 and another at $9000? Is the $9000 viscometer a better instrument? Why is there such a price difference between the two instruments?

Viscometer prices depend on both the make-up of the instrument's motor, and on the technical features of the instrument (temperature probe, speed range, USB compatibility, etc.). There are two main types of rotational viscometers: those using a spring motor, and those using a servo motor.

In this article, I’m going to take a look the options available for rotational viscometers, and how those options affect the price.

Read MoreTopics: Viscometers, Viscosity, Dynamic Viscosity, rotational viscometer, Liquid Properties