Static and Dynamic Contact Angle and Drop Shape Analysis

“Contact Angle (wetting angle) is a measure of the wettability of a solid by a liquid.”

If you need a more detailed examination of this phenomenon check out "Initiation to Contact Angle".

A drop of liquid on a solid surface. The drop, when in free state, forms a sphere. When it intersects with a surface the bottom, it flattens out. If the surface is highly wettable, the whole drop stretches out. If the surface is less wettable, the drop moves to a shape like a mushroom top. The angle between the solid surfaced and the edge of the drop is measured. (See sidebar.)

Who Cares About Contact Angle?

The contact angle or wettability between a liquid and a solid material substrate defines how the two will react. It determines how well a coating will adhere to such substrates as paper, plastic, or wood. This measurement is also an indicator of the cleanliness of a substrate. Here is a sample of industries and applications that use contact angle in their development and QC of products:

* Surfactants * Adhesives * Paint & Coating

* Ink * Bio-medical * Polymers

* Surface Quality * Fabric Design * Electronic Components

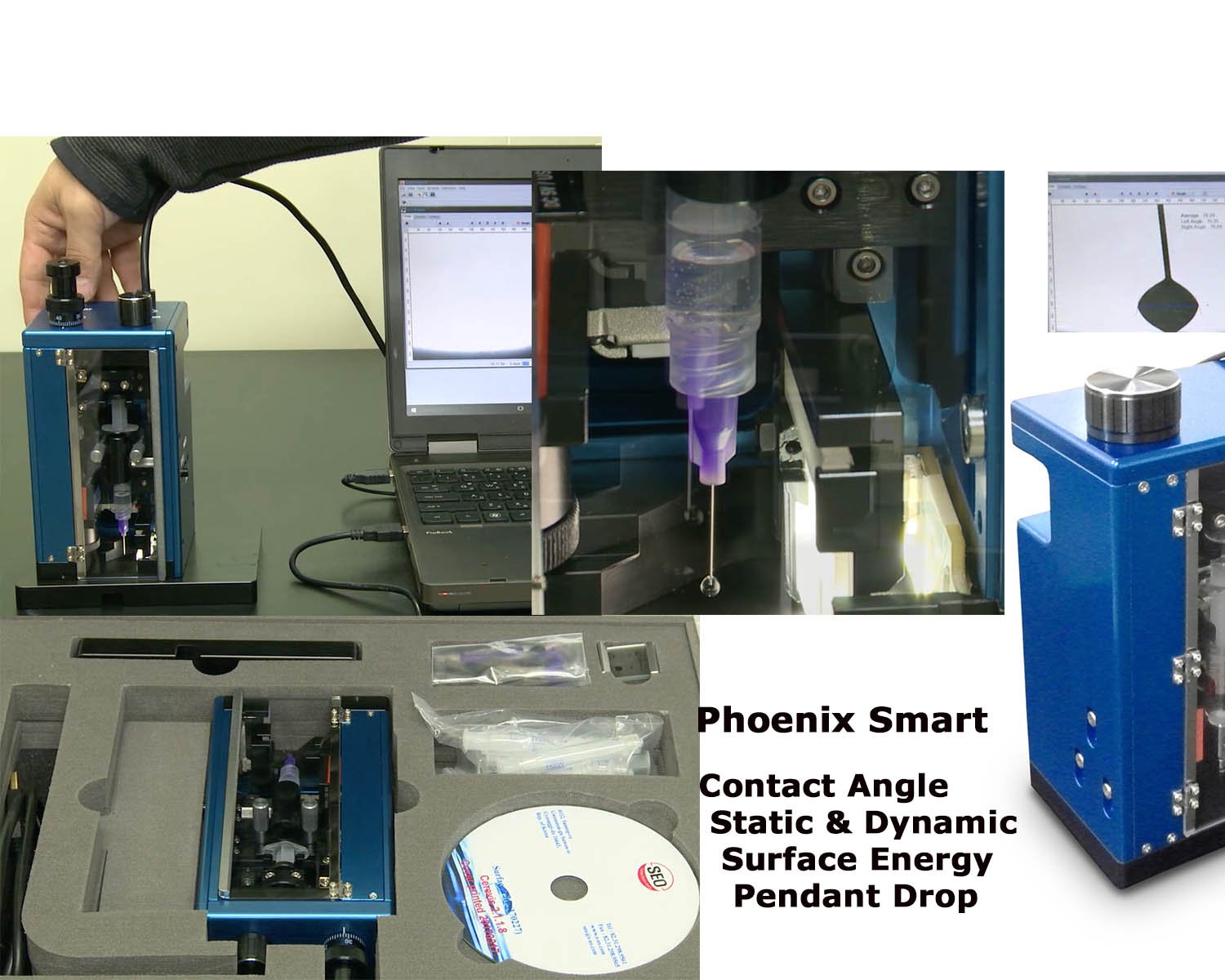

Static & Dynamic Contact Angle with the Phoenix Smart

As a drop reaches a surface it spreads out to wet an area. This is not an instantaneous process. Several factors affect the time to complete the wetting. Environmental factors such as temperature and the smoothness or roughness of the surface are among the factors.

A measurement when the process is complete is known as a static contact angle.

Dynamic contact angle is the contact angle which occurs in the course of wetting and is called the advancing angle. When de-wetting, the angle found is the receding angle.

One of the ways to measure this is to use a tilting stage. In this technique, a drop is placed on the substrate, which is then gradually tilted until just before the drop starts to move. The advancing angle is measured at the front of the drop. At this same tilt, the receding angle is measured at the back of the drop.

The Advancing Contact Angle and Receding Contact Angle can also be measured as the drop is emitted from the syringe and as the drop is sucked back into the syringe.

Other measurements that can be made with this instrument system are lubrication & wettness measured over a time period, measurement on a curved substrate, and pendant drop method for surface tension. Surface energy can also be determined.

How the Phoenix Smart Works

The Phoenix Smart System is a combination of hardware that controls the volume and transport of the drop and the SurfaceWare program that operates on computers with Windows 7, 8 or 10 installed. The program contains the image analysis and drop evaluation software that provides the contact angle details.

© 2023 CSC Scientific Company, Inc. All rights reserved.