Karl Fischer Titration and Loss-on Drying (LOD) are both methods for determining moisture content in a product.

That’s where the similarities end, though. In this article, I will explain the difference between Karl Fischer Titration and Loss-on Drying, and offer some suggestions to help you choose the right method for your application.

Read More

Topics:

Moisture Analysis,

Moisture Testing,

Karl Fischer,

Karl Fischer Titration,

Loss-On-Drying

Have you ever mixed up a batch of epoxy glue and, just before you finished the job, of course, had the mix unexpectedly turn into solid concrete? If you have, you experienced the effect of gel time. This term is a common measurement for products that thicken, cure, gel or harden when mixed. Product such as epoxies, adhesives, resins and coatings all use gel time measurements.

Read More

Topics:

Viscometers,

Viscosity,

gel time

In our business, we use the word “sieve” to describe a piece of equipment that separates different sized particles using a woven wire screen. To others, “sieve” can mean something very different.

Read More

Topics:

ASTM,

Particle Size Analysis,

Sieve Calibration,

Sieve Certification,

Sieves,

Sieving Process

It’s easy to pretend you know the operating terms surrounding contact angle measurement. But do you really? For industries such as coatings, printing, and oil recovery, contact angle testing is an essential component of the production and/or quality assurance process. Having a competent understanding of these terms will make it so much easier to choose the right instrument for your company - one you can be certain will do what you need it to do.

Read More

Topics:

Surface Tension,

contact angle,

contact angle meter,

dynamic contact angle,

Liquid Properties

Peltier temperature control is becoming more common in viscosity testing, but traditional water baths are still the norm for many companies. Should you switch Peltier-based temperature control for you critical samples?

Read More

Topics:

Measure Viscosity,

Viscometers,

Viscosity,

viscometer,

rotational viscometer,

differences in rotational viscometers

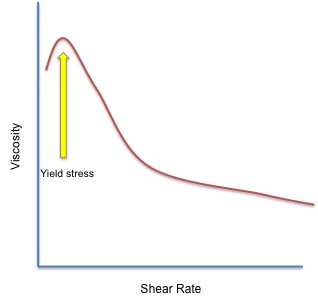

What are Viscosity Flow Curves?

A flow curve – also known as a rheogram – is a graphical representation of how a flowing material (fluid) behaves when it is subjected to increasing or decreasing shear rates. The corresponding shear stress and viscosity are calculated from the instrument’s parameters. You can tell what type of fluid (Newtonian/Non-Newtonian, thixotropic, dilatant, etc.) the sample is by the shape of the flow curve.

Read More

Topics:

Measure Viscosity,

Viscometers,

Viscosity

Moisture content is a critical factor to consider in the food industry. The amount of water in a product affects the product’s texture, shelf life, ease of processing, and cost to produce. Snack foods, baked goods, pet food, and dried goods are just a few examples of products that are vulnerable to moisture content issues like these. In many cases, an easy loss-on drying (LOD) test will allow you to monitor the moisture content of these products. (See the 3 Easy Steps to Run a LOD Test here.)

Simple moisture analysis can be all it takes to improve the quality of your product. Let’s take a closer look at how moisture content affects each of these four product and production aspects.

Read More

Topics:

Moisture Oven Test,

Moisture Analysis,

Moisture Testing,

CSC Digital Moisture Balance,

Loss-On-Drying,

Moisture,

fast moisture test,

moisture balance,

moisture content,

moisture measurement

“It doesn’t matter how it looks as long as it tastes good.”

This statement has long been my philosophy when it comes to cooking. The dishes I create usually taste okay – even really yummy, occasionally – but I stink at presentation. Family and friends are usually quite forgiving when it comes to their sensory (sight, touch, smell) experiences with a food. They tend to ignore looks and feel, and focus on taste.

Food buyers aren’t so forgiving. If their sensory experiences don’t meet expectations, that crucial first taste will never happen. Flavor isn’t everything, either. If the food doesn’t feel right, or pleasant, the first bite will also be the last.

Read More

Topics:

Texture Analysis

Looking at the rotational viscometers on the market today, you'd expect to see small price differences between the instruments offered by competing brands. But what if you find one viscometer priced at $2000 and another at $9000? Is the $9000 viscometer a better instrument? Why is there such a price difference between the two instruments?

Viscometer prices depend on both the make-up of the instrument's motor, and on the technical features of the instrument (temperature probe, speed range, USB compatibility, etc.). There are two main types of rotational viscometers: those using a spring motor, and those using a servo motor.

In this article, I’m going to take a look the options available for rotational viscometers, and how those options affect the price.

Read More

Topics:

Viscometers,

Viscosity,

Dynamic Viscosity,

rotational viscometer,

Liquid Properties

Most rotational viscometer specifications promise high test accuracy and repeatability. However, an instrument on its own cannot guarantee accurate results. Instrument set-up and using the right test parameters are critical pieces of the puzzle.

Test parameters and turbulence are two key factors to consider when preparing to test with a rotational viscometer. The spindle, speed setting, and temperature of the product are some of the parameters that can impact test results. Additionally, turbulence in the sample’s flow during a test will distort viscosity readings. Knowing how to manage these two factors can significantly contribute to the accuracy of your testing.

Read More

Topics:

Measure Viscosity,

Viscometers,

Viscosity,

Dynamic Viscosity,

rotational viscometer,

Liquid Properties