Have you ever mixed up a batch of epoxy glue and, just before you finished the job, of course, had the mix unexpectedly turn into solid concrete? If you have, you experienced the effect of gel time. This term is a common measurement for products that thicken, cure, gel or harden when mixed. Product such as epoxies, adhesives, resins and coatings all use gel time measurements.

Gel Time Explained

Gel time is defined as the point at which a product becomes too viscous to be workable. Knowing the gel time for a product gives an indication of the maximum time it is workable after mixing.

Gel time is defined as the point at which a product becomes too viscous to be workable. Knowing the gel time for a product gives an indication of the maximum time it is workable after mixing.

The calculation of gel time is made by tracking the change in the product’s viscosity over time. Most of the instruments that measure gel time operate similarly to rotational viscometers. These Gel Timers work by turning a spindle in a sample of the liquid product, and monitor the resistance to the spindle turning in the liquid. When the resistance gets high enough to keep the spindle from turning, the test stops. The time needed to get to this test stop point, or until the product becomes a gel, is measured and is known as the gel time.

Other Frequently Used Terms: Working Life and Pot Life

In addition to gel time, there are two other terms frequently used to quantify this process of curing: working life, and pot life. All three terms are often used interchangeably, which can lead to confusion.

Working Life is determined empirically, based on the rate of viscosity increase during the final stage of curing. The specification of working life is usually set by product suppliers as a means of identifying the theoretical limit of time the product is actually workable. For example, let’s say a product with a gel time of 15 minutes shows a rapid viscosity increase starting at 12 minutes. The supplier might then set the working life at this 12 minute point, or, to allow for a better margin of error, the specification may be set at 10 minutes instead.

Pot Life a specification set by the time it takes for viscosity to double. To illustrate, a product with a starting viscosity of 1,000 cP will be timed until it doubles to a viscosity 2,000 cP. If this takes 20 minutes, the pot life would be set at 20 minutes. An exception to this rule is for some products that have a very low initial viscosity. In these low viscosity products, pot life could be defined as the time it takes for the viscosity to increase by 4 times or more.

Pot Life is not a true indicator of the time a product is workable. It is most often used as a standard for comparison and evaluation of different products.

Using Gel Timers to Predict Workability

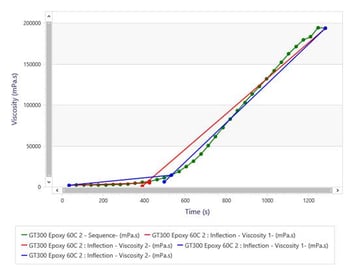

Modern Gel Timers record detailed viscosity readings during the test, often plotting data points as close as every one second. These readings are recorded and charted on special software. The graphing of these data points will show when the curing process starts. It can also track the rate of change in viscosity. Using vectors developed from this plotted data, predictions of realistic working times are extrapolated.

Modern Gel Timers record detailed viscosity readings during the test, often plotting data points as close as every one second. These readings are recorded and charted on special software. The graphing of these data points will show when the curing process starts. It can also track the rate of change in viscosity. Using vectors developed from this plotted data, predictions of realistic working times are extrapolated.

These Gel Timer systems create data-based, objective, real-time, predictive curves for determining the optimum period of time over which a product is workable.

Summary

At first glance, the concept of gel time appears clear and simple: How long before a two part epoxy glue turns to stone?

However, related terms such as working life and pot life are sometimes used interchangeably with gel time, and can be confusing if you don’t understand the terminology. I hope this article has helped cut through some of the haze.

If it has, and you found these jottings useful, please share them with colleagues who are involved with products that thicken, cure, gel or harden when mixed.

P.S. Did you know that you can subscribe to these exposés, rants, raves and ramblings? All you have to do is enter your email address into the box just to the right of the title.

P.P.S We have a full-featured Gel Timer with advanced analytical predictive software. Check out the GT-300 Plus. After you take a look, you can call me at 800-621-4778 or email me aranowsky@cscscientific.com with your questions and comments.

Till next time,

Amanda