It’s easy to pretend you know the operating terms surrounding contact angle measurement. But do you really? For industries such as coatings, printing, and oil recovery, contact angle testing is an essential component of the production and/or quality assurance process. Having a competent understanding of these terms will make it so much easier to choose the right instrument for your company - one you can be certain will do what you need it to do.

So here’s a test: our P-Smart Portable Contact Angle Meter measures contact angle using what’s known as the sessile drop method. With the P-Smart, you can conduct both static contact angle measurements - using the time-dependent method - and dynamic contact angle measurements - using the captive method. It’s also able to measure surface tension using the pendant drop method.

Did your eyes just glaze over from all of those terms? It’s ok to admit it, because you won’t be in the dark anymore after reading this article. I’m going to define these basic contact angle operating terms, and explain how they fit into the work of the P-Smart, so you can know if the instrument will work the way you need.

What is Contact Angle?

Let’s start off with the most basic principle: what is contact angle? Contact angle is the angle at which a drop of liquid meets a solid surface. It quantifies the wettability of a substrate (surface). What is wettability? It’s how much a droplet of liquid spreads out on a surface. Non-wetting surfaces would have big droplets of water on them (think of a waxed car). Wetted surfaces would have the water spread out on them.

So, how do contact angle meters actually measure contact angle? One method stands out above the rest: the sessile drop method.

How the Drop is Made

The sessile drop method is by far the most commonly used method to measure contact angle. It involves a syringe pump to produce the droplet of liquid (usually water), and a camera to observe the droplet on a substrate. Software connected to the camera is used to identify and calculate the contact angle of the droplet on the substrate.

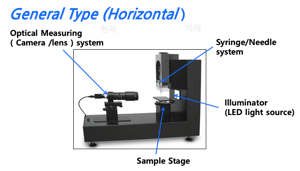

There are two ways to set up a sessile drop test. The first is known as the “general type” (also known as “horizontal type”). In this case, the camera is pointed horizontally, parallel to the substrate, to view the droplet. [See picture] This general type of the sessile drop method is usually used in benchtop contact angle meters.

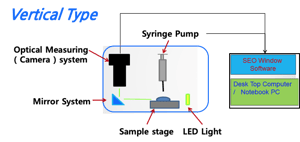

The other way is called “vertical type”. In this case, the camera points downward, perpendicular to the substrate. A mirror is angled so that it reflects the image of the droplet toward the camera. The P-Smart Portable Contact Angle Meter utilizes the vertical type of the sessile drop method. [See picture]

Now that we’ve identified how the images are captured, how does the software work to take the readings that will be used in analysis?

There are two types of contact angle measurement: static contact angle and dynamic contact angle. Let’s start with measuring static contact angle. The P-Smart uses the time-dependent method, which is the most commonly used method for measuring static contact angle.

Measuring Static Contact Angle

The time-dependent method measures the drop shape as a function of time. With the Portable Contact Angle Meter, you can easily track the changes in your droplet’s shape over time. Track the changes manually, by capturing single images of the droplet as often and at whatever time you choose, or automatically, by running a sequence capture, which will capture the images at intervals which you pre-set.

One of the uses for static contact angle measurement is a for determining cleanliness, an important step, for example, in the production of silicon wafers and circuit boards.

For dynamic contact angle, the P-Smart uses a method called the captive method.

Measuring Dynamic Contact Angle

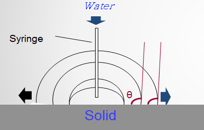

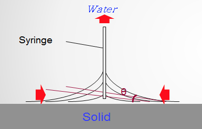

The captive method utilizes the syringe to actively inflate or deflate the droplet during the measurement. A droplet is made on the surface, and then, with the syringe still attached to the droplet, more water is added (to measure advancing contact angle), or water is removed (to measure receding contact angle) from the droplet. [See picture]

What are advancing and receding contact angle, you ask? Advancing and receding contact angle refer to contact angle as measured when the droplet is in a state of movement, like when the substrate is tilted. Hence, dynamic contact angle.

Advancing Contact Angle

Advancing contact angle is produced while the liquid is flowing onto the solid. When looking at a droplet that is on a tilted surface, it’s the angle measured on the side of the droplet that is facing downward.

Receding Contact Angle

Receding contact angle is the angle produced when the fluid is drawn away from the solid. When looking at a droplet that is on a tilted surface, it’s the angle measured on the opposite side of the direction the droplet is moving.

The difference between advancing and receding contact angle is called contact angle hysteresis, and is an indication of surface roughness. The roughness factor can be crucial in coating applications.

Sometimes, it can be important to know the surface tension of the liquid as well as the contact angle. How can a contact angle meter be used to measure the surface tension of the liquid in the syringe? The P-Smart does so using a popular method called pendant drop.

Using a Contact Angle Meter to Measure Surface Tension

Pendant drop surface tension is measured as a droplet of liquid hangs from the tip of the syringe. The size of the base of the droplet, the liquid’s density, and the force of gravity all go into the calculation, which is automatically detected and generated by the Portable Contact Angle Meter’s software.

Surface tension measurement is most often used in conjunction with contact angle measurement when the liquid being used for testing isn’t water. It helps to qualify the effect that different liquids have on the substrate.

Summary

The P-Smart Portable Contact Angle Meter is an instrument you can take just about anywhere to conduct your contact angle, surface analysis, and surface energy tests. Need to check the cleanliness of your surface on the spot? Done. What if the surface you want to test for coating ability is too big to fit into a benchtop instrument? Just stick the P-Smart right on top.

But proximity isn’t the only thing you need to consider when you’re purchasing a new contact angle meter. Not all contact angle meters work the same way, and sometimes there are different technical levels offered for the same model (the P-Smart, for example, has a manual version and an automatic version). By understanding these contact angle meter operating terms, you’ll be better able to judge if the meter you’re looking at will do what you need it to do.

Now that you’re more familiar with the many operating terms surrounding contact angle, how can the Portable Contact Angle Meter work for you? Let us know in the comments below.

P.S. You can subscribe to these articles and newsletters by placing your email address in the space to the right of the title.