You probably know that rotational viscometers work by measuring the torque on a vertical shaft that rotates a spindle. The spindle is in the test sample and its rotation is impeded in proportion to the viscosity of the sample. These instruments measure viscosity.

That’s pretty simple.

Most rotational viscometers also have a similar appearance. There are, however, two significantly different torque measuring systems used by rotational viscometers. This option is not readily apparent when you look at different viscometer models.

Spring Systems

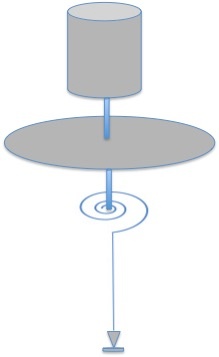

As the name implies, this system uses a design incorporating a spring. This system uses a spring to capture the torque tension on the spindle.

As the name implies, this system uses a design incorporating a spring. This system uses a spring to capture the torque tension on the spindle.

These systems use sets of calibrated springs. Manufacturers using the spring system offer three to four spring ranges. Each range is related to a span of viscosity. Three to four individual instruments are needed to cover the standard range of viscosity (1 cps to over 100,000,000 cps).

A spring viscometer system is based on a pivot and spring concept. A pivot/spring assembly rotates on the shaft. The spindle is attached to this assembly. As the spindle rotates, the drag of the fluid against the spindle causes the spring to deflect. This deflection is proportional to the torque caused by the viscosity of the sample. This relationship to viscosity is calculated automatically.

The spring system provides high measurement accuracy, particularly in the low viscosity ranges. This advantage is offset by the limited measuring range of any single spring/pivot set or instrument.

Because it is a somewhat delicate system based on a spring structure, special care is needed to protect it from undesirable influences and damage. Further, as with all spring systems, calibration needs to be checked and adjusted frequently.

Servo Systems

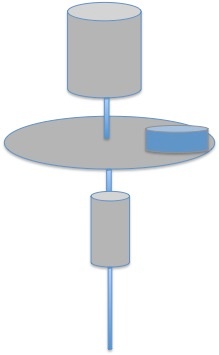

A second system for getting at the torque is sometimes known as the servo system. This uses a precision servo motor to drive the shaft. The spindle is attached directly to the shaft instead of a pivot, as with the spring system.

The current needed to drive the shaft at the test speed is determined. This current determination is made using a servo encoder, which determines the rotational speed, and a micro processor, which calculates the current needed to drive the servo at the set speed. As the spindle rotates, the drag of the fluid against the spindle makes the system use more current to keep the spindle running at the set speed.

The current is an indirect measure of the torque, but it is proportional to the viscosity.

Servo system viscometers provide a wide range of viscosity (for example 1cps to 100 million cps) in a single instrument. Also these systems are more robust than spring systems. Further, servo systems allow for greater torque and speed ranges. Re-calibration of servo systems is rarely needed.

Because there is some additional friction in the servo systems, the accuracy for slow speeds and lower viscosity is less than for spring systems.

Spring and Servo Viscometers Look the Same

Except for some differences in spindle mounting designs, it is difficult to tell a spring system viscometer from a servo system viscometer. The principal differences are:

1. Servo systems typically cover a viscosity range from 1 cps to 100 million cps.2. Spring systems usually require four different instruments to cover the same range as servo systems.

3. Servo systems rarely need calibration.

4. Spring systems need frequent calibration (more frequent with more use).

6. Price range for basic servo system viscometers is $3,500 to $4,000.

5. Price range for basic spring system viscometers is $2,500 to $3,500. There is a class of dial reading spring system viscometers that are priced at approximately $2,000.

The Selection Puzzle

We have found that there is a significant difference between the basic measuring systems of rotational viscometers. Your next thought is, doubtless, “So what? Why should I care?”

As with most measuring systems each of these types come with an array of options such as touch screens, programmable tests, data management and automatic test control. These options are not part of this narrative.

Rather, financial and operational consideration of the basic and frequently unnoticed different torque measuring systems are germane to intelligent viscometer model selection.

The difference between the two measurement systems (spring and servo) has implications on operational factors such as the level of attention needed for calibration checking, recalibration effort and record keeping activities.

The higher cost of the servo system would be decisively overcome, if the measurement needs spanned more than one spring system range. In this context, only one servo system would be needed vs at least two complete spring systems.

We hope that this discourse on the differences between viscometer torque measuring system brings some aid in the evaluation of rotational viscometer models.

As we continually prove to ourselves. What first appears as simple instrument questions leads to intricate answers.

Hope this was helpful. Please share this message with colleagues who work with viscosity.

- Art and Amanda

P.S. Did you know that you can subscribe to these exposés, rants, raves and ramblings? All you have to do is enter your email address into the box just to the right of the title.

P.P.S. Check out a couple of Vicsometers.