A classical definition of Contact Angle:

“Contact Angle (wetting angle) is a measure of the wettability of a solid by a liquid.”As usual, this simple definition is fraught with hidden agendas. These agendas need to be identified because wettability and thus contact angle are important measurements.

Processes that relate to oil recovery, lubrication, liquid coating, printing, surface cleaning and many other industries use contact angle to define product specifications and as benchmarks for quality control.

Now we try to work our way through the puzzle - or should I say fog - of multiple agendas.

Basics of Contact Angle Measurement

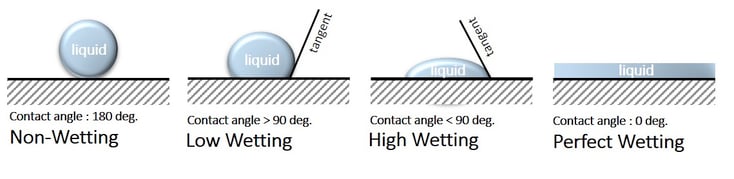

Let’s start simply with a picture of a drop of liquid on a solid surface. The drop when in free state forms a sphere (or, as some say, a state of of minimum surface area). When it intersects with a surface the bottom flattens out. If the the surface is highly wettable the whole thing stretches. If the surface is is less wettable the drop moves to a shape like a mushroom top.

Here is where the basic measurement begins. The angle between the solid surfaced and the edge of the drop is measured.  This is the contact angle. A small angle (less than 90 degrees) means the surface is favorable for wetting. If the angle is larger than 90 degrees the solid tends to be difficult to wet.

This is the contact angle. A small angle (less than 90 degrees) means the surface is favorable for wetting. If the angle is larger than 90 degrees the solid tends to be difficult to wet.

These measurements are known as static contact angle.

Liquid Surface Tension and Solid Surface Energy

Before we more further into wettability, we need a word about liquid surface tension. This is the property of a liquid that keeps it from flying out into space. Surface tension is the trait that gives a free state drop its spherical shape (more about this in an article titled What are the Primary Conditions Affecting Surface Tension?).

For a given solid, a liquid with low surface tension will produce more wetness than a liquid with high surface tension.

Another prominent factor affecting wettability is the surface energy of the solid.

To illustrate, imagine the unwaxed hood of a car. In this state the hood has high surface energy. Water placed on the unwaxed hood spreads out and wets the hood. Compare this to placing water on a low energy waxed hood where the water beads up and does not wet the hood.

Pretty simple stuff — Not yet.

The Story of Contact Angle Measurement

Let me digress one more time. The concept of contact angle has been around for more than a hundred years. The early apparatus was cumbersome to use and contact angle measurement was mostly confined to the university laboratory.

With development of modern Goniometer equipment the procedure was greatly simplified. The coatings, adhesives and lubricating industries viewed these easy goniometer measurements as a new way to predict the performance of their products.

It turned out, though, that these early contact angle measurements often did not correlate with real world results.

Why not? The new Goniometers were easy to use and turned out precise data. It should be noted that these Goniometer measurements were made on a flat smooth surfaces.

Reality set in...

Most Real World Surfaces Are Not Smooth

The coatings, adhesives and lubricating industries worked not with flat smooth surfaces but with with real world surfaces that are not smooth, but have indentations, pits and scratches. It turns out that drops on these surfaces don’t follow the tidy rules of shape and wetness found on smooth, flat solids.

On these rough and non-level surfaces, the drops flow and take time to settle down. Sometimes the drops sink into the indentations and sometimes not. If the surface is porous, some of the drop might be absorbed.

Then, what happens if the drop is on an incline?

Huh. We begin to see that the drop is influenced by more than just the surface tension of the liquid and the surface energy of the solid. Pits and scratches raise their ugly heads. The drops are no longer uniformly shaped, but stretch and bubble.

What Does A Drop Do On Real World Surfaces?

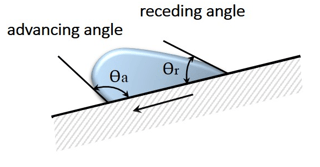

In observing this reality, the contact angle observations noted that the drops on one side often have a different contact angle than on the other side. Angles were less in the direction of flow or on the down side of an incline.

New terms were coined to describe these phenomena. The different contact angles on a specific drop caused by movement or inclines are known as advancing and receding contact angles. The measurement of the different contact angles on a drop is called dynamic contact angle.

New terms were coined to describe these phenomena. The different contact angles on a specific drop caused by movement or inclines are known as advancing and receding contact angles. The measurement of the different contact angles on a drop is called dynamic contact angle.

Another term has been applied to the difference between advancing contact angle and receding contact angle. This difference is called contact angle hysteresis.

As experience with wettability measurement has developed, the hysteresis concepts have proven to have predictability and correlation with real world conditions in coating and lubricating systems.

Leaving Contact Angle Hysteresis For Now

I'm going to quit before this meander gets even more complicated. I’ll take on the implications and techniques of contact angle hysteresis in a later ramble.

This one has really stretched me past my usual capacity to move through technology fogs.

If you are using or contemplating using contact angle measurement in your work, I hope this has brought you a useful perspective. Please share this with associates who do similar work.

Until the next discourse on dynamic contact angle and contact angle hysteresis, thanks for visiting with us.

Art

P.S. Did you know that you can subscribe to these exposés, rants, raves and ramblings? All you have to do is enter your email address into the box just to the right of the title.

P.P.S Check out our contact angle meter offering: