Motion to the Sample in a Test Sieve

While trying to get the noise out of the test sieving process we must keep in mind other issues associated with sieve shakers

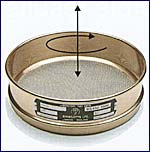

Effective sieving motion presents all particles in a sieve to all of the sieve openings and assists particles to pass through the sieve openings. This requires both rotary and vertical motion. To do this in a whisper quiet way is a goal.

More About Sieve Shakers

There are three essential characteristics to look for in a good sieve shaker.

It should generate an effective sieving action for tests to reach an ultimate end point.

The end point should be reached in the shortest possible time.

The results achieved should be reproducible.

For consistent, reproducible results the correct sieving action is all important

As manufacturers of test sieves we understand how sieves and shakers interrelate.

As manufacturers of test sieves we understand how sieves and shakers interrelate.

A sieving sample must rotate over the full surface of a sieve where it can be presented to the maximum number of apertures in the minimum time.

In addition, a vertical movement must be imparted. This vertical movement continuously helps clear the sieve apertures and avoids them blinding while insuring that all particles, that fit, will fall through the apertures.

Traditional shakers operate with a loud, annoying and damaging (to a persons hearing) noise.

Two shakers are available that meet the motion needed for quick effective sieving (rapid progress to a reproducible end point) and a refreshing almost noiseless (we call it whisper quiet) operation.

These are the Octagon and the Meinzer II.

Misc

Primary Purpose of a Sieve Shaker