Concerns such as salt and acidity, flow behavior, thickness, spoilage, and shelf life all affect the quality and consistency of production processes. With the right tests, you can monitor those concerns to understand how they affect your product, and predict how your product will behave in production and during customer use. Click the blue links below to learn more.

"Did you know viscosity can tell you all about things like spreadability, mouth feel, and melting behavior in food?"

"Did you know viscosity can tell you all about things like spreadability, mouth feel, and melting behavior in food?"Viscosity testing can tell you a lot about how your food or beverage product will behave in different scenarios. Since the test is related to flowability, the product must be in a liquid state during testing, or at least be stir-able. For instance, you might think of mashed potatoes as a solid, but you can still stir them with a spoon. Therefore, they can be suitable for viscosity testing.

R&D specialists use viscosity testing when they're formulating a product for many of the same reasons a manufacturer would use viscosity testing in the production plant:

Some products, such as chocolate, have National and International Standards for testing their viscosity. Chocolate viscosity testing is hugely important for showing how the product will flow in a pumping process, cover (coatings), and fill (fillings).

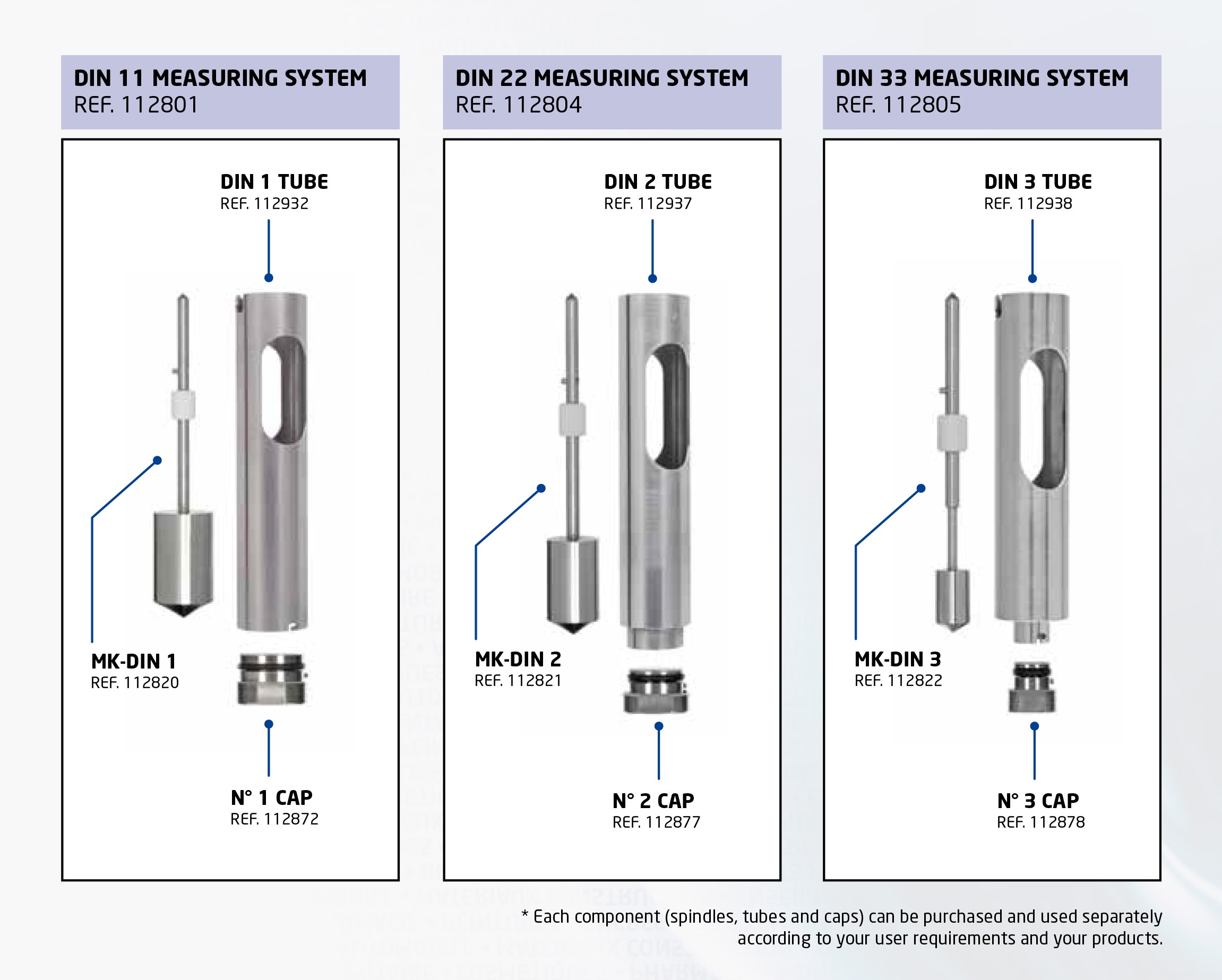

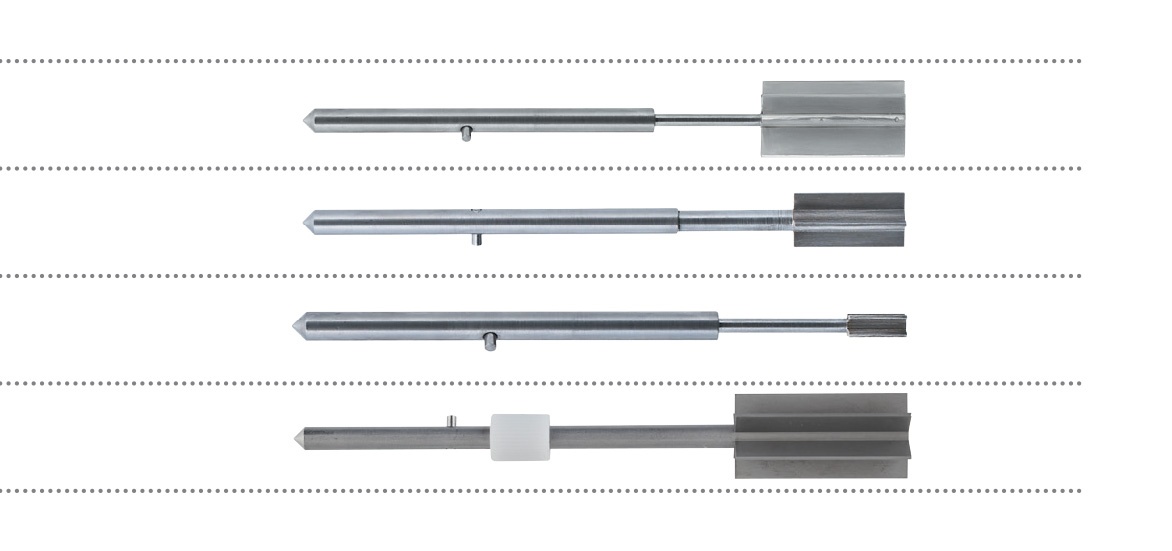

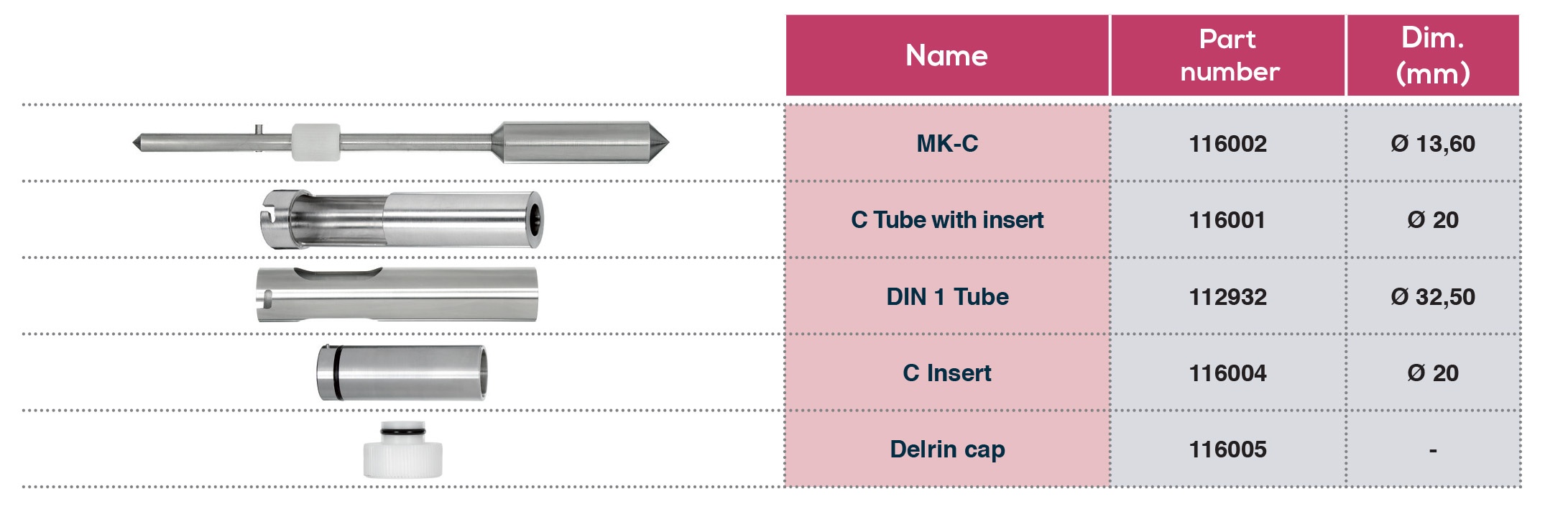

There are many different spindle options that are suitable for testing food and beverage products.

"Ever noticed that not all ketchup brands are the same? I do. You might say I'm a ketchup aficionado."

"Ever noticed that not all ketchup brands are the same? I do. You might say I'm a ketchup aficionado."Testing with the consistometer is often mistaken for viscosity, so let's make it clear from the start that consistency and viscosity are NOT the same thing. While both measurements involve examining how a product flows, the consistometer is an empirical test that can only tell you how far your product spreads under its own weight in a given amount of time. Every company will create its own unique standards for their product.

The Bostwick Consistometer offers a quick and easy one-point test for measuring the product's relative ability to flow. Originally designed for testing ketchup, this instrument is good for testing smooth products that are neither very watery nor so thick that they won't flow of their own accord. Condiments, smooth (flowing) batters, and smooth sauces are appropriate for testing with the consistometer.

Measuring density or specific gravity is

Measuring density or specific gravity is

Samples in this category include milk, dairy products, soft drinks, carbonated drinks, fruit juice, soy milk, etc. Density or Brix is measured for quality control purposes during production process and/or before shipment.

Samples in this category include beer, wine, whiskey, Japanese sake and other liquors. Pricing can be subject to Alcohol Concentration or extract, and taxation subject to alcohol degree.

Samples in this category include raw materials such as honey, syrup, concentrated extract, saline water, isomerized sugar, etc. Soy sauce, Worcestershire sauce or barbecue sauce is checked for taste control by measuring Brix or Concentration of target substance.

Quality of vegetable oil and animal oil are controlled by measuring Density or Specific Gravity.

"Alas, the numerous and unique challenges we face measuring moisture content in food samples!"

"Alas, the numerous and unique challenges we face measuring moisture content in food samples!"Loss on Drying (LOD) analysis will provide you with the total water content in your sample. The digital moisture balance is a useful tool for total moisture content analysis. Its simple design and ease of use make this moisture balance convenient for many essential food production applications.

Loss on drying, by its very nature, means that we are drying the sample and, in the process, heating the sample. It was discovered that the total loss or mass loss caused by other volatile substances present if the initial food sample itself or created during the heating process led to some erroneous conclusions. Oils are an example of a volatile substance that can burn off in addition to the moisture and possibly give incorrect results. If your samples do not have a problem with other material burning off and the accuracy of 0.2% is accurate enough, then this approach may work best for you.

Loss on drying is used in the following scenarios:

Why would I want to use a volumetric Karl Fischer titrator instead of one of the other methods like loss on drying? Loss on drying in some cases cannot avoid undesirable side reactions with volatile substances, and/or achieve good reproducibility with food samples that contain really low-level moisture content.

A volumetric Karl Fischer titrator on the other hand can provide not only a way to get around the side reaction problems found with volatile substances, but also provide much greater accuracy and repeatability. A Volumetric Karl Fischer titrator can measure moisture with Parts Per Million (PPM) accuracy from as little moisture as 10 PPM up to 100%.

Food, by its very nature, comes in many shapes and sizes. Liquids, solids, complex carbohydrates, simple sugars, fats and oils, alcohol, starches, grains, flours, and cheeses, to name only a few, present unique challenges when determining moisture content.

The ADP-344 (Heat Extractor) accessory unit extracts water content from a sample in the dehydration solvent by heating the titration cell of the volumetric Karl Fischer Moisture titrator. This unit is ideal for measuring the water content of chocolates, caramels and other sugar samples.

The ADP-611 is a traditional solids evaporator that connects to the volumetric Karl Fischer Titrator where a bubble tube delivers the evaporated moisture directly into the titration cell. Typical samples that might require an evaporator would include solids or powder that might not dissolve easily in the titration cell. Other reasons for using the evaporator might include keeping the titration cell clean and free of messy samples. This approach can also extend the life of the solvents being used as the titration cell will fill less quickly.

The ADP-611 is a traditional solids evaporator that connects to the volumetric Karl Fischer Titrator where a bubble tube delivers the evaporated moisture directly into the titration cell. Typical samples that might require an evaporator would include solids or powder that might not dissolve easily in the titration cell. Other reasons for using the evaporator might include keeping the titration cell clean and free of messy samples. This approach can also extend the life of the solvents being used as the titration cell will fill less quickly.

In general, working with a volumetric Karl Fischer titrator, the operator has the freedom to open a port on the titration vessel to introduce a sample without affecting the final results.  This approach works very well, regardless of the type of sample being tested. This can include powders and solids. The key to getting good results by directly introducing the sample into the vessel is finding the right solvent mixtures to dissolve the sample. Composites and Titrants come in different strengths and can be used to address a variety of sample testing issues including how well the sample will dissolve and the level of moisture content being measured.

This approach works very well, regardless of the type of sample being tested. This can include powders and solids. The key to getting good results by directly introducing the sample into the vessel is finding the right solvent mixtures to dissolve the sample. Composites and Titrants come in different strengths and can be used to address a variety of sample testing issues including how well the sample will dissolve and the level of moisture content being measured.

"Shelf life and packaging are two important concerns facing food production and processing professionals."

"Shelf life and packaging are two important concerns facing food production and processing professionals."Water activity is an important measurement for determining food shelf life. Water activity (aw) measures the free water on a substance. The FDA regulates water activity in food products to ensure that sufficient water is not available to support bacteria, yeast or mold growth during storage. Water activity is frequently measured for many food products including:

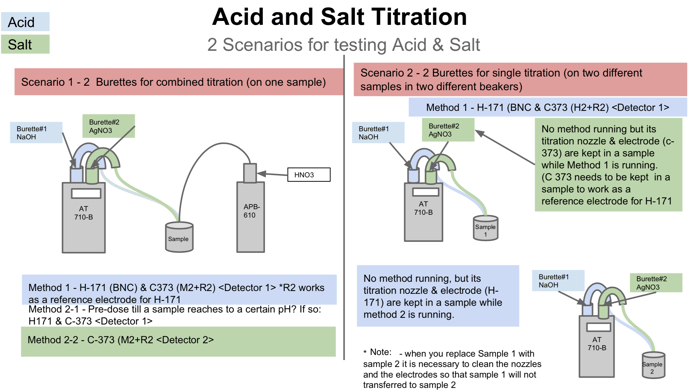

"Salt and acidity are important tests performed by QA/QC and production departments. Hands down, these are the two most requested food titration tests companies ask about."

"Salt and acidity are important tests performed by QA/QC and production departments. Hands down, these are the two most requested food titration tests companies ask about."A "salt" titration can be performed manually or by using an automatic titrator. A popular titration method known as Mohr's method determines the chloride ion concentration. Silver nitrate is used as the indicator and is added until all of the chloride ions are precipitated. This method measures the amount of chloride (Cl) and uses the mass percent weights to determine sodium chloride (NaCl) and or sodium (Na). Mohr's method can be performed manually or by using an automatic titrator.

There are a number of "acids" that require measuring in the food industry. Here are a few:

For these types of acid titrations, Sodium Hydroxide (NaOH) is used. In cases where both salt and acid testing is required, there is the capability to combine and run both tests on one sample. See the scenarios below.

"Refractometers not only measure refractive index but also Brix (surcrose) which is found in many beverages and foods."

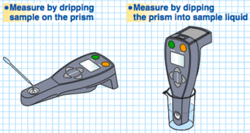

"Refractometers not only measure refractive index but also Brix (surcrose) which is found in many beverages and foods." Measuring sucrose levels with a refractometer requires a specific scale known as "brix". Whether you're looking for a refractive index or brix result accuracy is dependent on the capability of the device you are using. In general, you will find Benchtop refractometers can provide the largest variety of test capability with the best accuracy. However, sometimes all you really need is a simple handheld unit. Always check to make sure the range you need can be performed by the device you choose.

Modern benchtop refractometers are better equipped with temperature controls and fancy touch  screen interfaces. Refractive Index (nD) and Brix are standard measurment items but can include other items like concentrations.

screen interfaces. Refractive Index (nD) and Brix are standard measurment items but can include other items like concentrations.

Handheld refractometers are convenient. Finding one that covers the ranges for measurement that you need can sometimes be a process. Many portable refractometers are configured for a select range to accommodate a particular application such as honey or milk. Finding one with a larger range is sometimes a better option if it is unclear what types of samples may be tested.

If all you need to know is the sucrose level, then forget about all the other stuff. Just get a handy, no frills, Brix Meter. But, as with portable refractometers, make sure the brix meter you get covers the range you need. Sometimes brix meters can be set for specific brix ranges.

Fruits and vegtable growers rely heavily on brix readings. Knowing the ideal time to harvest is very important to ensure flavor and quality. In general, knowing the brix level helps manufacturers monitor sucrose levels at numerous points in the harvesting and production stages of foods containing sucrose.

"We discovered that brewing and beverage makers in particular were running many samples per day to get density/specific gravity and refractive index results. So, it made sense to address this problem."

"We discovered that brewing and beverage makers in particular were running many samples per day to get density/specific gravity and refractive index results. So, it made sense to address this problem."The ASCA-6400 presents a new concept of analysis, consisting of a high-precision Density/Specific Gravity Meter, a Refractometer and a newly-designed Gondola-transfer Sampler, all built in the single compact chassis.

Features:

"If you're looking at packaging your beverage product and automation is important, then consider a Gas Volume and Internal Gas Pressure Analyzer."

"If you're looking at packaging your beverage product and automation is important, then consider a Gas Volume and Internal Gas Pressure Analyzer."Simply set a sample container on the sample stage, and then all the procedures are performed automatically: punching, depressurizing, stirring of the sample, absorption of measurement gas, and so on. By continuously rotating a sample container, the balance pressure of gas and sample temperature in the container are measured and calculated into gas volume/internal gas pressure. Additionally, carbon dioxide in the sample gas is absorbed into an alkaline solution to leave only nitrogen and oxygen, and then calculate air content using the residual gas volume and oxygen concentration.

Features: